Jesel Pro Aluminum Shaft Rocker BBC Install

Before you do anything, always read the instructions. The install was performed in January of 2018. This install was not performed by Multi Motorsports, LLC. The customer allowed us to document the install. We wanted to give this shaft rocker kit a good run through before posting a write-up because even over a year later, it needs no adjustment.

This car has exchanged many parts within the past few years and this is not even the most recent update, but we hope to be shedding some light on all of that soon. With the hood removed and the amount of fender covers used, we can see this customer still cares about the 10+ year old paint on the car. If this car ever sees any rain, it is due to a bad weather forecast. The lack of windshield wipers and the 18.5” pontoons on the rear of the car make it quite a problem in the rain.

The engine consists of a Dart Big M 565 cubic inch block (the engine has been in there so long that nobody is sure on which Big M block it is) and Brodix BB2-XTRA heads with ARP head studs. The head studs used are designed for a Brodix engine block with Brodix Heads. ARP does not offer a head stud kit specifically for a Dart Big M block with Brodix heads. You will see from the photos shown below that some head studs protrude farther than others.

With the valve covers removed you can see the original setup: Harland Sharp roller rockers with PRW billet aluminum stud girdles.

After reading the instructions and familiarizing yourself with all of the components, always test fit your hardware before attempting a full and securely torqued install. The number 1 cylinder was the first to be fitted and the washer for the bolt that joins the intake and exhaust rocker stands together hit the head stud. We removed some material from the washer so it will clear the head stud. ARP said that 2-3 threads sticking out from the nut is normal and this has 3-4 threads. Not an issue at all since this was such a simple fix.

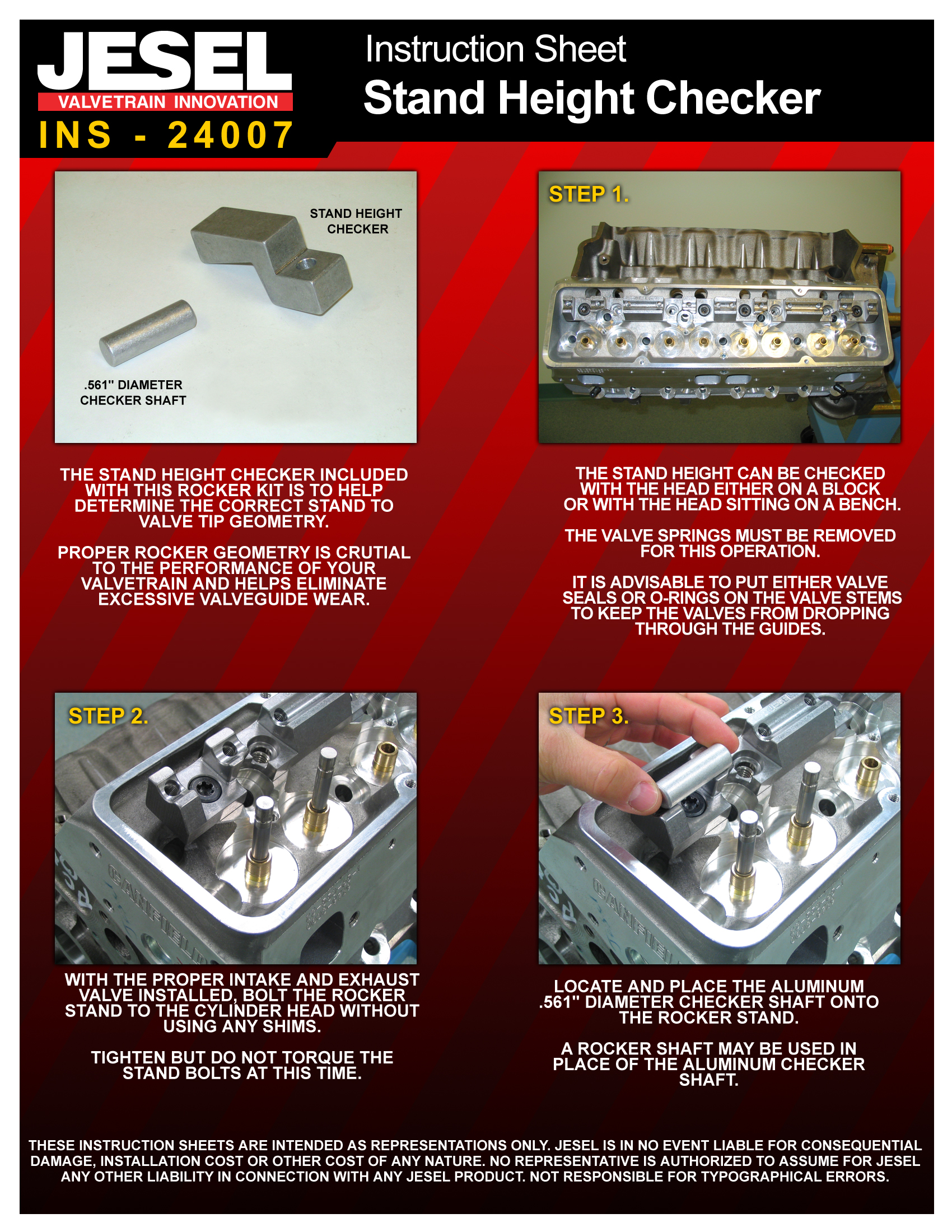

The kit did come with spacers and 2 different sets of bolts, varying in length, for the rocker stands. The use of spacers is determined by using the Jesel stand height checker. After checking the stand height, it was found that no shims were needed for this application, but Jesel recommends using the longer bolts if you can. Please read the instructions regarding the stand height checker before using.

The #1 cylinder rocker stands and the joining bolt were torqued to spec and the remaining Harland Sharp roller rockers have been removed. When installing the remaining rocker stands, there was a problem with the exhaust stands hitting certain head studs. There was 6-7 threads protruding from the nut for the head stud. This could be because certain head studs did not go far enough into the engine block because they were designed for a different engine block. This goes back to using head studs for a Brodix engine block and heads on a Dart Big M block with Brodix heads. Jesel offered to remedy the issue, but the customer wanted to handle this himself by removing 1/4” of material from the corner of the exhaust rocker stand. In the 4th photo, the yellow circles are where the joining washers hit head studs and the red circles are where the exhaust rocker stand hit head studs.

You can see from the photos shown below what the customer did with a traditional grinder on 6 of the exhaust rocker stands. Jesel was highly against this because the integrity of the rocker stand has been compromised. We recommended this be sent back to Jesel to be resolved, but the customer wanted to resolve this himself. Jesel was not responsible for any of this, but it was amazing to see them step up to resolve this. Once fitment of all rocker stands was completed, the stand height checker was used on all rockers and it was found that no shims were needed on any of the stands, and all fasteners were torqued to spec. Rockers were installed on the #1 cylinder to check the pushrod length.

Jesel’s TOL-29400 pushrod length checker was used to see how much our pushrod length has changed and if we would be able to use the existing pushrods. Please read the instructions before using.

Due to the many times this engine has been modified with different blocks, heads, intakes, cams, lifters, and rocker arms, there was a large selection of spare pushrods to choose from.

Original pushrod length: intake 8.550”, exhaust 9.450”.

New pushrod length: intake 8.450”, exhaust 9.300”.

An exhaust pushrod length of 9.350” would have been preferred, but it was possible to adjust the difference without exceeding Jesel’s recommendation of 1/4 turn up to no more than 2 turns on the adjustment from the adjusters seated position. The intake adjustment was 1/2 turn from the seated position and the exhaust was 2 turns from the seated position. Once the driver’s side was complete, all was moved to the passenger side. The same testing and checking procedures were done. All stand heights were checked. During rocker arm adjustment, make sure you do not exceed 2 full turns from the adjusters seated position. If you do, you need to check the pushrod length again.

Throughout 2018, the rocker arms have been checked a few times and all were found less than 0.010” out of adjustment once, some none at all, and the other times there was nothing found out of adjustment. The engine uses an Isky camshaft and Isky solid roller lifters with bushings instead of roller bearings. The overall setup has been proven to be very reliable with almost no maintenance and no rebuilds over the past 5 years since the engine was originally assembled and installed into the car.

THIS ARTICLE AND ITS CONTENT ARE INTENDED AS REPRESENTATIONS ONLY. MULTI MOTORSPORTS, LLC AND JESEL, INC ARE IN NO EVENT LIABLE FOR CONSEQUENTIAL DAMAGE, INSTALLATION COST OR OTHER COST OF ANY NATURE. MULTI MOTORSPORTS, LLC IS NOT AUTHORIZED TO ASSUME FOR JESEL ANY OTHER LIABILITY IN CONNECTION WITH ANY JESEL PRODUCT. MULTI MOTORSPORTS, LLC IS NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.